Wood is one of the materials that we use for a lot of things, like furniture, houses and other daily use items. Specifically regarding wood cutting it has many measures by work piece shape needed to cut tend head such as plank 1-dimension or block => assist sawing device band vastly vice versa. For cutting wood, people use various types of saws that are intended for his purpose. Reciprocating saw Many people prefer to use a reciprocating say and find it very useful. This type of saw features very fast moving blades that go back and forth which results in a smooth cut through the wood.

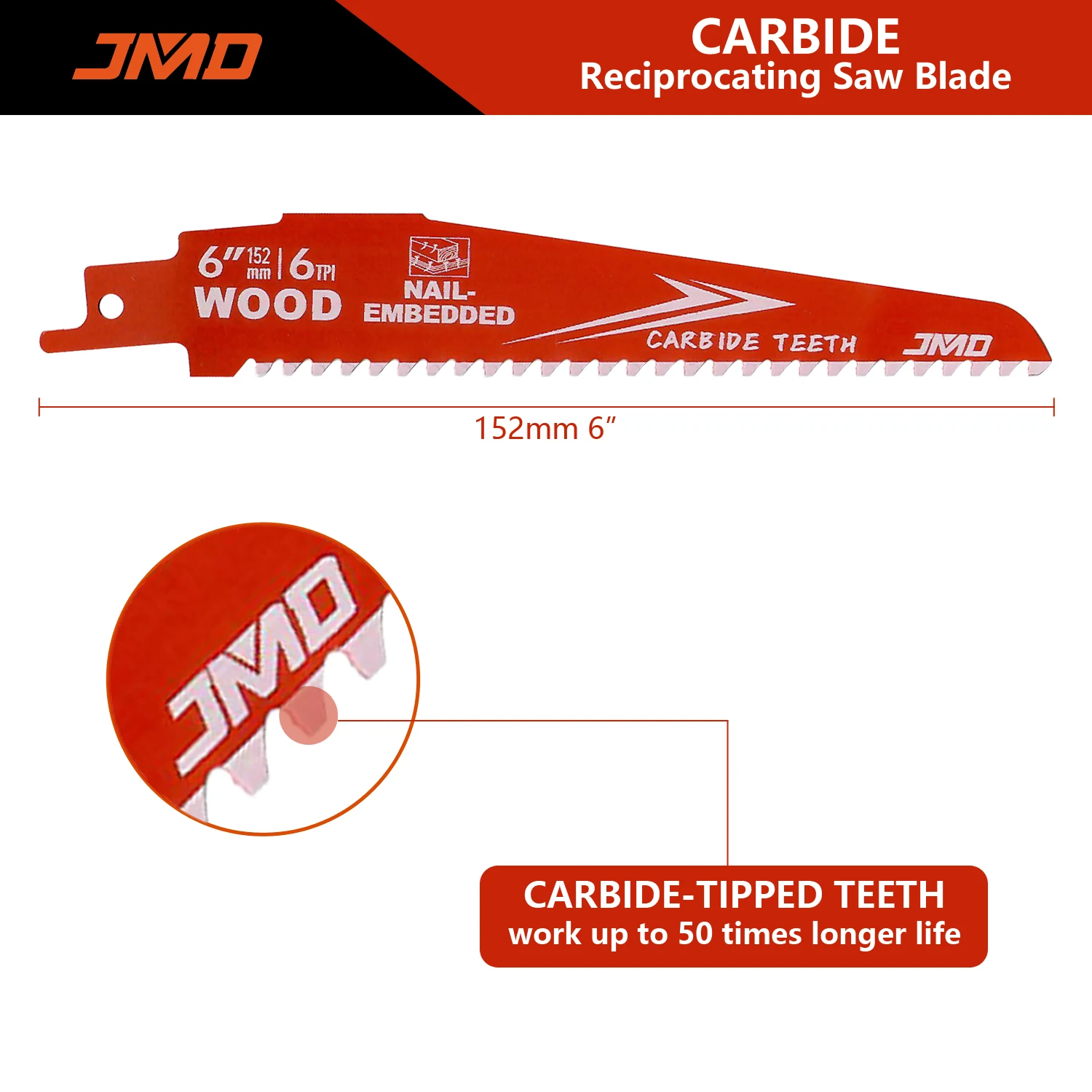

Reciprocating Saw Blades for Wood Cutting —- These are some of myriad types of blades which were used to cut wood with reciprocating sawSPM. They are designed for cutting wood and they have enough power to ensure that the blade remains sharp without getting dull prematurely, which in turn gives you a long service life out of the teeth. These blades can be used to cut hardwood, which is denser and more difficult species of wood; they are also useful for cutting softwood which is less dense compared to their counterparts. These blades are incredibly versatile for working with a variety of materials.

This article explains some of the most important attributes these saw blades have, and why they do a fantastic job. You can use them to cut down large pieces of wood such as those massive beams that you see around construction sites, or smaller tree boards which will be used in furniture production. You can use dplyr to do so many things you really get a wide range of tasks under one tool. These blades can also help you to perform various cuts. This means whether you need precision straight cuts that create a sharp edge or more complex curves for more intricate designs these blades can do it all.

These blades are also supremely tough and robust so you can see why I rank these as some of the best rotary cutter Blades. That allows them to run for long periods of time without breaking or otherwise dying. This is a great thing to have as the last thing you would want, especially if your in the middle of cutting something is for you blade to snap so that means stopping what tour doing and starting again with another blade. This can be a headache to painful process. All the same, if you have a well-made and resilient blade on hand while doing so; then there is no trouble about proceeding past without any other thought its snapping. This allows you to complete your task faster.

This is due to the right work blade for your cutting requirement giving a perfect cut. Reciprocating saw blades for wood cutting are specialized and perform well only in the method of chopping timber. They are precise and can be used to make fine cuts so that you always have the wood cut exactly as it is supposed to. This is crucial as fits together correctly, your projects will look better and perform more efficiently. When you a fashioning an object of furniture or any structure having correct cuts can have the utmost significant influence on how it comes out.

There are a lot of advantages to utilising these saw blades and it can assist you greatly so. Well to begin with they can save you a ton of time. They are so sharp and dexterous you do not have to fiddle a long time trying to find the perfect cut. You will be more enabled to work faster and effective. Secondly, they are cost-effective as well. Because when you have a sharp, high quality blade that will last for years there is no requirement to keep purchasing new blades which can get expensive. Third and maybe most importantly, these blades are what enable you to build better things. Improving wood cutting means you can shave that end piece down a bit and get it to fit, tricking yourself into thinking its still square. It will allow you to have sharper, safer tools and that can mean better results in all your woodworking projects.

We have put in place our quality control system is extremely strict during our production process. Every stage manufacturing is thoroughly monitored and examined to ensure that only items of the best quality leave factory. Our quality control team is equipped state-of-the-art testing equipment and adheres strict guidelines conduct thorough testing of products. This meticulous approach helps determine and fix any quality issues before the products arrive at our clients. In keeping these high quality standards, company ensure satisfaction for our customers and create long-lasting relationships based trust and wood cutting reciprocating saw blades.

Our factory has gained invaluable information and experience working with leading brands and customers the industry for more 20 years. The extensive experience has allowed us to comprehend the specific requirements and demands our clients. This allows us create custom solutions and services. Through a number of successful partnerships we refined our production procedures, improved the quality control processes, and developed deep wood cutting reciprocating saw blades of the market's developments. Our long-standing standing in business is result of our dedication to excellence and our ability deliver consistently high-quality services products.

We employ a group with highly skilled technicians committed pursuing cutting-edge technology throughout year. This team is dedicated to innovative thinking and is always on the lookout of the most recent trends in the market. Their experience and expertise allow the company to develop new products that not only surpass, but even exceed the expectations customers. We make sure that our products remain relevant and stay at the forefront of the latest trends. Continuous wood cutting reciprocating saw blades in R and D allows us to develop unique solutions and stay on forefront of our field.

We are proud to achieve the ISO9001:2015 certification our quality assurance system and also BSCI and BEPI. These certifications speak to our unwavering commitment to maintaining the highest standards of excellence, ethical sourcing, and environmental accountability. The ISO9001:2015 certification assures us that our quality control systems are robust and efficient, ensuring consistent product quality. The BSCI certification and BEPI certification wood cutting reciprocating saw blades our commitment to social and environmental compliance well as sustainable business practices. Our customers have assurance that the items they purchase were made with respect for the environment and ethical conditions.