Types of jigsaw blade:- Types Specifies Small Thin Jig saw Blades Cold also comes Questions Different Design Shapes Size They connect to a jig saw machine and incredibly slowly cut through metal. By cutting carefully, we mean that you want to cut straight; and when considering the design algo would also be attentive. This is crucial for producing metal objects since the cuts must be straight so that the pieces will fit together properly and one can have a good finished product. This is the reason they are referred to as jig saw blades. They used to reduce the intensive work of metal and as a result, we could produce metals in different shapes, sizes or you can say structures that are useful for many types of working processes.

Yes, it has made some of us ask; have you ever seen jerky metal working courtesy to a jig saw machine? It looks really cool! This long blade, moving rapidly up and down through the metal it severs with utter ease. What many people may not be aware of is that, in order to work properly the blade has to have durability and longevity.

What we mean when a blade is efficient, it means that it takes less time to cut through metal and the edge won´t break easily. This durability makes sure that the blade stays sharp and never breaks down for a long, long time. Jig saw blades used in work with metalwork, the process of making items using metals should possess such qualities.

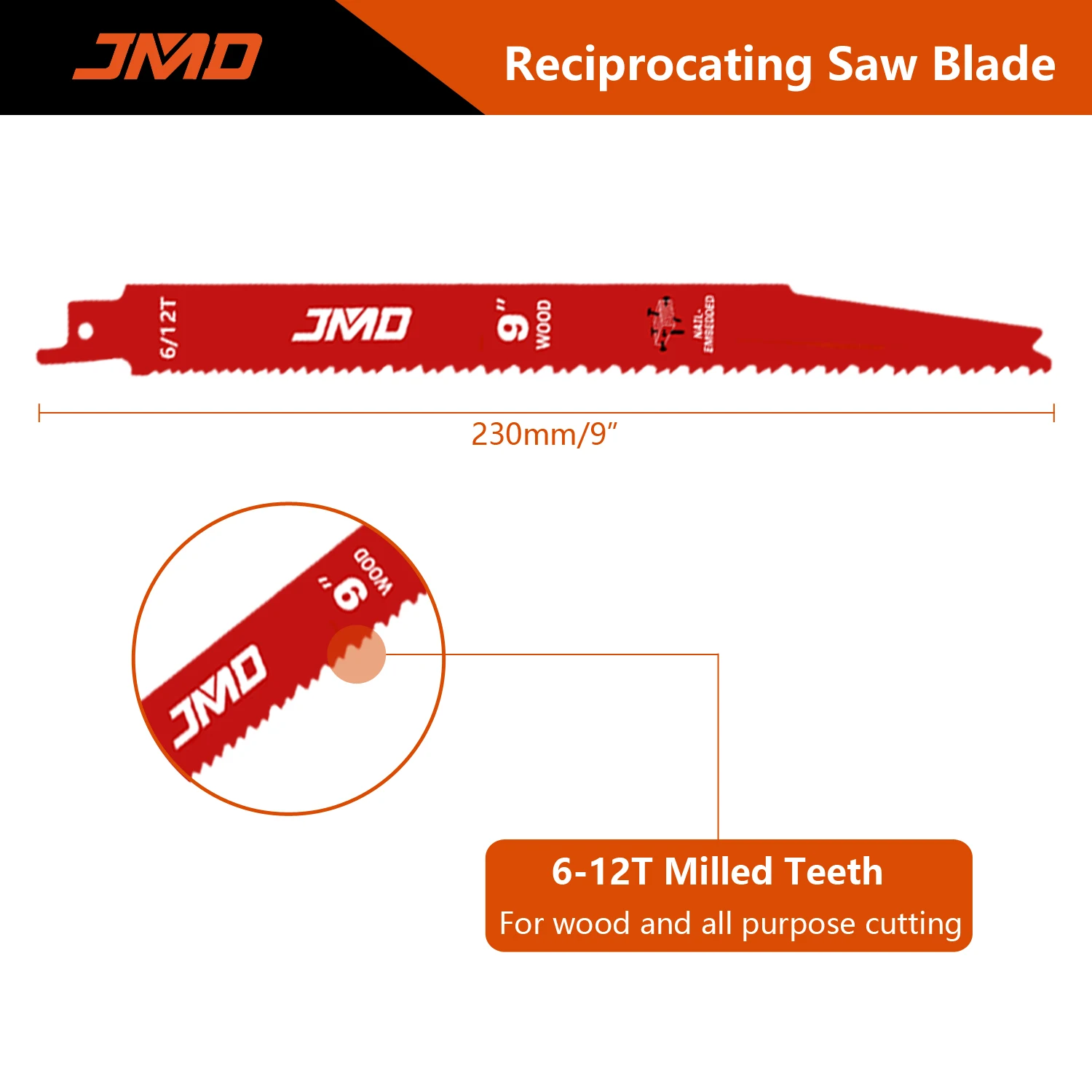

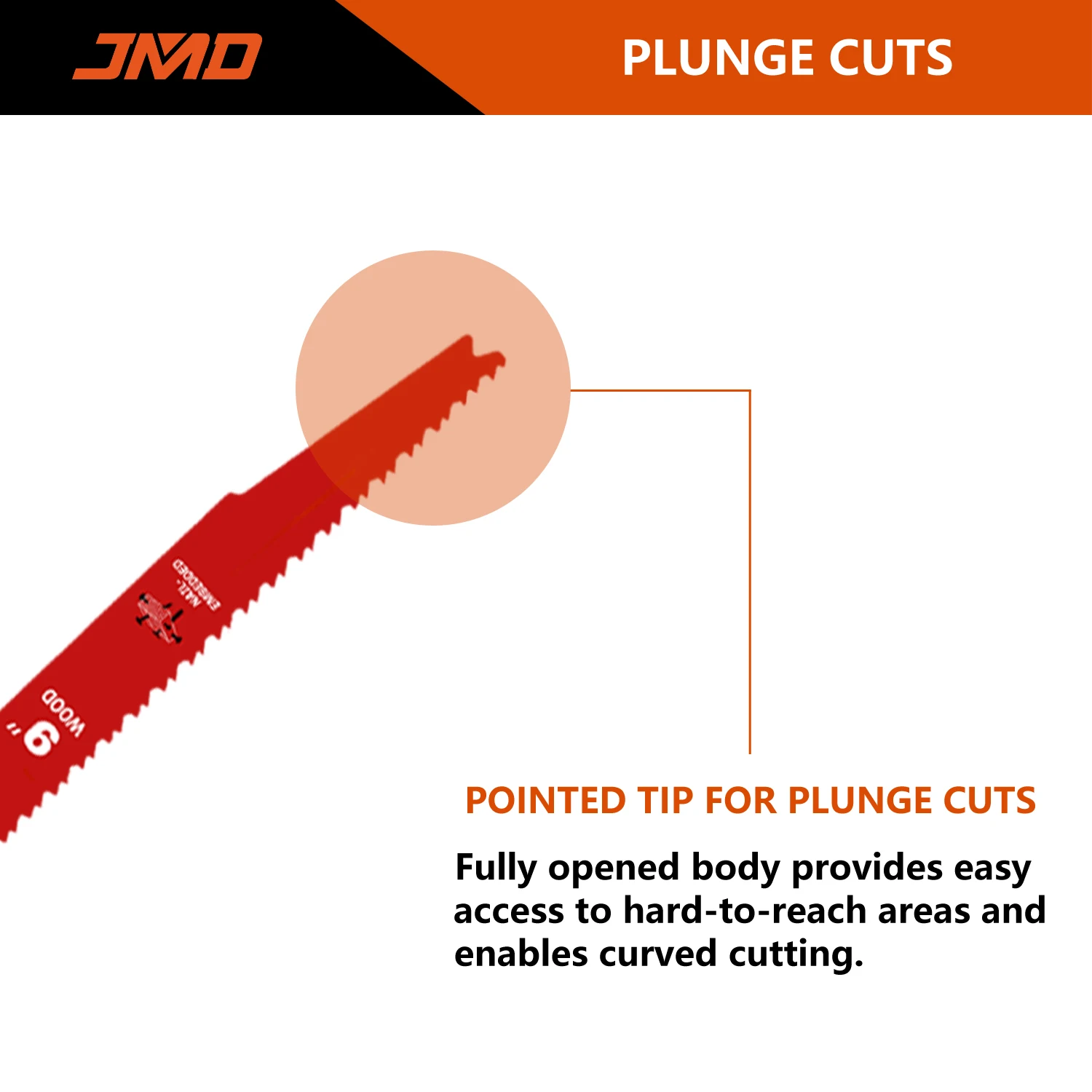

Picking the Suitable Jig Saw Blade for Metal Cutting You need a blade that will cut through metal fast and wont buckle or snap with all the pressure. The teeth and edge of the jig saw blade should be sturdy, in addition to being built from robust materials that give it strength like high-speed steel. This enables the blade not to quick wrinkle and it lasts long with efficiency.

CBSI (really?] There is a multiplicity of metals out there, did you know? Metals can be soft, sometimes requiring simple sharpness to penetrate... or hard as steel - much more daunting for those who do not appreciate the metal-working experience...and then I explore still others with great curiosity. Here the unique part is that different metals have its own properties to cut out so cutting them specially require more care.

This is why you should also consider using jig saw blades that can handle a wide variety of materials. It can be used for various projects and applications, thanks to the versatile blade appropriate for different metal cutting tasks. It can save time and effort to a great degree owing to its flexibility in nature for working on diverse metal types.

In addition, there are jig saw blades design especially for cutting certain metals such as aluminum or stainless steel etc. Others can even saw through most of the metals (see Top-Metal-Cutting-Band-Saw-Charts) which is extremely helpful. To ensure accurate and efficient cutting, it is crucial to choose the appropriate blade for each job. Avoiding this will save you from getting messy cuts or destroying the blade itself.

We are proud to achieve the ISO9001:2015 certification our quality assurance system and also BSCI and BEPI. These certifications speak to our unwavering commitment to maintaining the highest standards of excellence, ethical sourcing, and environmental accountability. The ISO9001:2015 certification assures us that our quality control systems are robust and efficient, ensuring consistent product quality. The BSCI certification and BEPI certification jig saw blades metal our commitment to social and environmental compliance well as sustainable business practices. Our customers have assurance that the items they purchase were made with respect for the environment and ethical conditions.

In our production process, have implemented exceptionally strict quality inspection process. Every stage jig saw blades metal monitored and checked to ensure only the finest products leave our factory. Our quality control staff is equipped with state-of-the-art testing equipment adheres strict guidelines to conduct thorough testing of products. This methodical approach enables us to spot any potential problems products and rectify these before our products can reach our customers. We assure our clients' satisfaction maintaining strict high standards quality. This allows us to build relationships built on trust and reliability.

Our team consists of highly-trained technicians are committed to pursuing cutting-edge technology throughout entire year. This team is committed innovation and always looking out for the latest trends in the marketplace. Their knowledge and experience allow the company to develop new products that not just satisfy also exceed requirements of the market. We make sure that our products are always jig saw blades metal and competitive by keeping up-to-date with the latest trends. Continuous effort in R and D will allow us to develop unique solutions while remaining at the top our game.

Our factory has gained invaluable understanding and expertise by working some of the most renowned brands customers in the industry for over 20 years. Our vast experience has enabled us to gain better understanding of our clients' specific requirements and requirements, which enables to provide customized solutions and services. Through a variety of successful partnerships, we've refined production methods, strengthened quality control processes have developed a profound understanding the market's dynamics. Our long-standing renown in industry is a reflection of our commitment to excellence as well as our capacity to consistently deliver superior products jig saw blades metal.