A hacksaw blade is a very useful tool when it comes to cutting metal. The hard part is that there are so many different modes — how do you know which one to use for your document? In this post, I help you with a hack saw blade guide to understand different types of hacksaw blades and how to use them properly for cutting metal.

But before we discuss how to select the correct blade, here are some useful hacksaw tips. One of the most important parts to start with can be verified by ensuring that your blade is secure and locked in place. As this helps the blade to grip and cut more efficiently, which works well at lower speeds too; preventing a bent or broken blade due to erratic jerking currents during work. The massively secured blade will facilitate your cutting process more smoothly and safely.

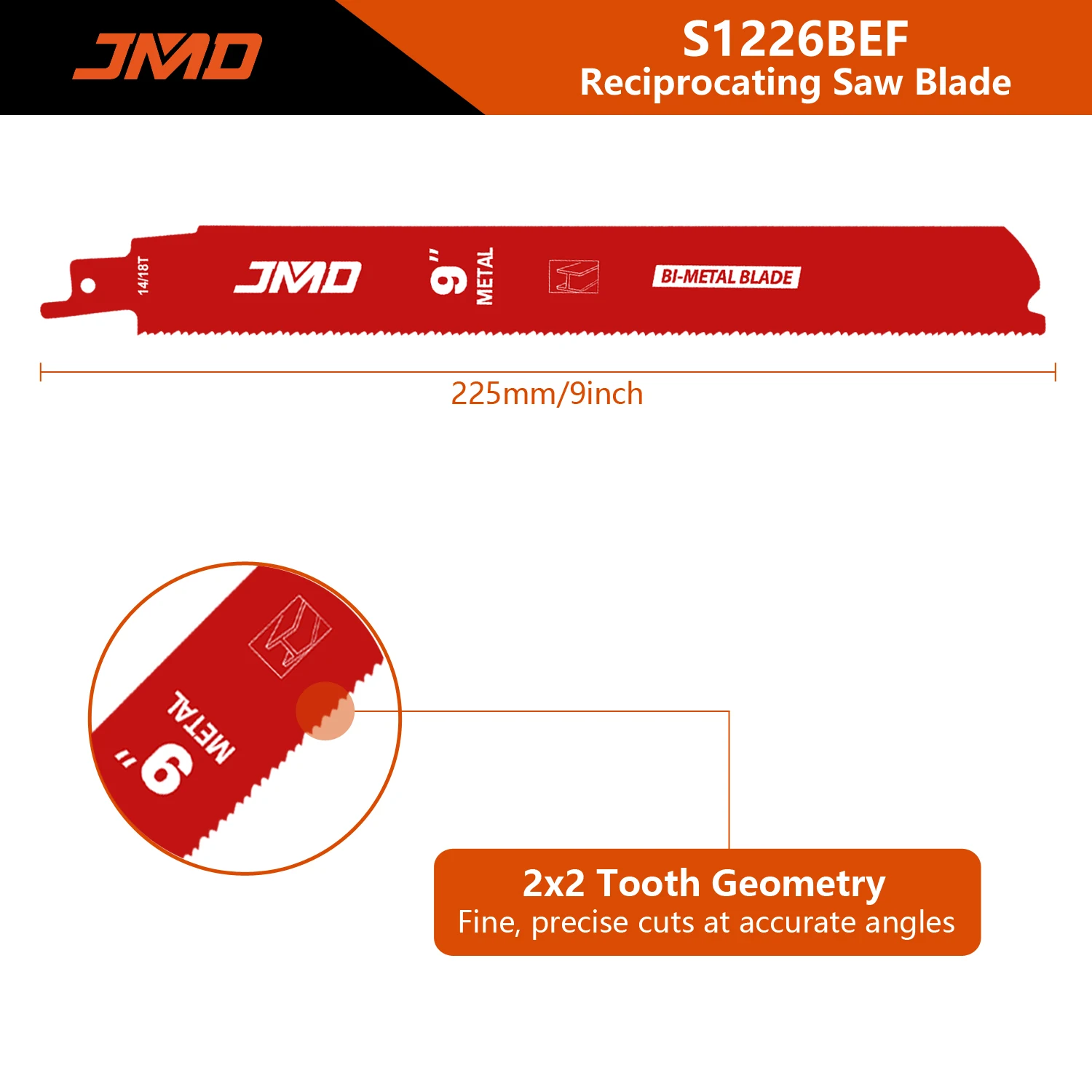

After that, you should select the most suitable blade for your cutting operation. For thinner metal, then you will want to use a blade with more teeth per inch (TPI). This means that the blade will provide more precise cuts, which is ideal for working with thinner materials. Alternatively, the more teeth per inch of a blade should be used if you are only cutting thicker sections of metal This is so because it can maximize the removal of cutting material at once that helps to cut more quickly.

Finally, it is also well lubricated with a single slice. Lubrication helps the blade to slide through the metal, leaving a clean cut and keeping it from becoming dull too fast. A well lubricated blade functions better and lasts longer so do yourself a favor — take the time to lube your blades!

Here are a few ideas on some cheep hacksaw blades Labor Day to keep your saw up and running: Be prepared Hassocsvsr. If you notice the following, it might be time for new blade Haveshastaencv3 :- Signs That You Really Need To Change Your Hacksaw Blade significantly improve Where Can I Buy A Sawzall?

Measurement of the MetalThickness: The first thing to do is find out how thick the metal you will be cutting. A blade with higher number of TPI is recommended for thinner sheets of metal. But, when cutting thicker material such as metal a blade with less TPI will be optimal for the heavier thickness.

3rd) The form factor to the shape of teeth and blade config; The raker-set blade is ideal for cutting softer metals; conversely, the wave-blade set works well with harder materials. Selecting the appropriate tooth configuration will have a huge impact on how well the blade works for your particular cutting needs.

We have a team of highly-trained technicians are determined to study cutting-edge technologies all year. This team is dedicated to innovative thinking and is always in the know about the latest market trends. They are able to create unique products that exceed and exceed the market's expectations. In keeping ahead the market, we can ensure hacksaw blades for cutting metal line remains fresh, competitive, and relevant. We are able to offer unique solutions investing in R and D.

With more than 20 years of extensive experience working with some of most prestigious brands clients in the field, our facility built up a vast knowledge base know-how. Our vast experience has enabled us gain a better understanding of our customers' unique requirements expectations, allowing us offer tailored services and solutions. Through a myriad of partnerships have been successful, we've refined our production methods, strengthened our quality control measures, and developed a deep understanding the market's dynamic. Our long-standing standing the industry is a reflection of our commitment to hacksaw blades for cutting metal our ability to consistently deliver superior products services.

We are proud to that we have successfully completed ISO9001:2015 quality certification, along with BSCI and BEPI certifications. These certifications show our commitment to the very highest standards of quality, ethical sourcing and environmental responsibility. The ISO9001:2015 certification assures us that our quality management systems strong and effective, which ensures consistent product quality. The BSCI and BEPI certifications prove our commitment to sustainability and hacksaw blades for cutting metal compliance practices, allowing our customers with the confidence that our products are produced in environmentally-friendly ethical conditions.

In our manufacturing process, we have hacksaw blades for cutting metal exceptionally thorough quality inspection system. Each step the production process monitored and inspected to ensure only the best products leave manufacturing facility. Our quality control staff is equipped with the latest testing equipment, and strictly adheres to protocols to conduct thorough testing of products. This methodical approach allows us spot any potential quality problems address these before our products can reach customers. Through the strictest quality standards, we ensure satisfaction for our customers create long-lasting relationships built trust and confidence.