Demolition blades are simply a special kind of large tool that plays an essential role when it comes to breaking down any building or structure. They displace so they can replace. And think of these as a big knife, but much stronger and more powerful. These blades come in various sizes and shapes depending on what they are designed to do. That means you will need different blades to do the job efficiently for various tasks

Demolition Blades There are several demolition blades that you will come across. Some of the knives are bought for casual use, meaning they all work well on those small jobs. Rough use – Includes stronger materials and more-heavy-duty blades. Using the wrong blade can make a big difference in your work. Yes, with the right demolition blade and it is going to be done quicker then nearly any work other than less efficiently.

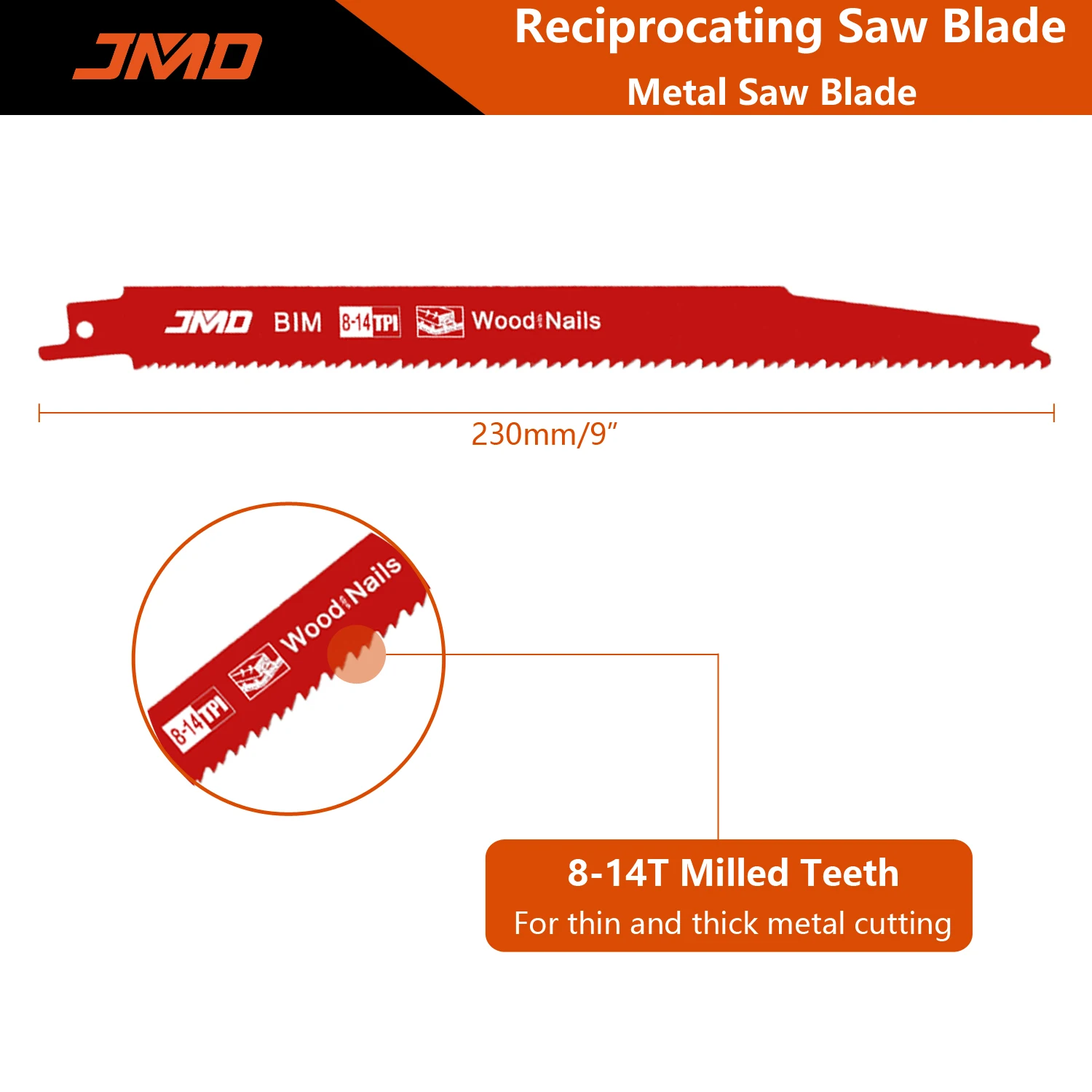

Drill machine — to bore a hole in rock, concrete or brick using a core bit. JMD demolition reciprocating saw blades and bits that are made of hard material for cutting tough stuff like metal. Additionally, the teeth in these blades are sharp and this is very important as you need to tear down the material. As for a demolition blade, It works by almost laying over whatever material you are trying to remove. This type of material crumbles under pressure, making it easy for you to remove. Knowing how these blades function can help you stay safe and efficient.

Demolition Blades Heaviest duty demolition blades built for the most demanding environments. Demo blades generally tend to be significantly larger and heavier than the standard demo blade. Therefore, the JMD reciprocating demolition saw blades can achieve tasks more difficult without collapsing. These heavy-duty blades are constructed from durable material to give you long-lasting performance, and they can also retain power for an extended period helping you not have change them frequently. It durability absolutely critical when it comes to these larger projects where a lot of material must be sliced and ground away.

Lasts for Years High abandon of clothes is predicted to return with the heavy use demanded year after yr from it They are made so that the materials do not break down easily, thus limiting its lifespan of how long it can perform efficiently. Which in turn means that you can use them time and again for any number of projects before they approach rusty. Longevity One of the very concerns you need to have when acquiring a demolition blade, is just its service life. A durable blade also means that you have to replace it less often saving you time and money in the long run.

In addition, the demolition blades are made to be more durable so they perform better. Any construction material needs to be strong and durable because it is produced from high-quality metals, Which effortlessly copes with the most difficult cutting tasks around. Job blades allow you to quickly as well as efficiently cut for top-quality amment. This JMD demolition sawzall blade is particularly important in demolition operations, as this ensures a free and good work.

Our team consists of highly-trained technicians are committed to pursuing cutting-edge technology throughout entire year. This team is committed innovation and always looking out for the latest trends in the marketplace. Their knowledge and experience allow the company to develop new products that not just satisfy also exceed requirements of the market. We make sure that our products are always Demolition blades and competitive by keeping up-to-date with the latest trends. Continuous effort in R and D will allow us to develop unique solutions while remaining at the top our game.

Our factory has gained invaluable understanding and expertise by working some of the most renowned brands customers in the industry for over 20 years. Our vast experience has enabled us to gain better understanding of our clients' specific requirements and requirements, which enables to provide customized solutions and services. Through a variety of successful partnerships, we've refined production methods, strengthened quality control processes have developed a profound understanding the market's dynamics. Our long-standing renown in industry is a reflection of our commitment to excellence as well as our capacity to consistently deliver superior products Demolition blades.

We are incredibly proud to be able to successfully obtain ISO9001:2015 accreditation for our quality system, and also BSCI and BEPI certifications. These certifications demonstrate our commitment to the highest standards in quality as well as ethical sourcing and environmental accountability. The ISO9001:2015 certification ensures our quality control systems are reliable and effective, ensuring constant product quality. The BSCI certification as well as the BEPI certificate demonstrate our commitment to social compliance and sustainability business practices. Our Demolition blades can have assurance that items they purchase were made in environmentally friendly and ethical conditions.

Our production process is extremely rigorous, and have implemented a thorough quality inspection system. Each stage of production closely monitored and inspected to ensure that only items of finest quality leave our manufacturing facility. Our quality control team is equipped the latest testing equipment and follows strict protocols to conduct comprehensive product testing. This meticulous approach helps us discover rectify any problems with our products before they arrive at our Demolition blades. We ensure our clients' satisfaction maintaining strict high standards of quality. This allows us to establish relationships based on reliability and trust.