Do you ever find the need to cut metal or other tough materials when working on your projects? Well, you just need to learn about Power hacksaw blades of course! Building Solutions, Salvage Building MaterialsComment on Circular Saw Blades by Kate RichardsThese special blades are tools which were specifically designed to cut heavy-duty materials. They are capable tools that exert their muscle to assist you in making cutting an easier, quicker process compared with when using regular saws.

Whether you are at a construction site where concrete and metal drilling is often needed or on the road, it always serves having high-quality tools. The best power hacksaw blades for this type of work are all designed to be as hard-wearing and supportive as possible. They make quick swift cuts on hard materials by sheer force of their sharp teeth. They are also freshly picked electrically, making your cuts more convenient and less laborious. This allows you to get your project done with more energy and thought process without killing yourself.

Don Woody points out that while accelerating and completing your projects as soon there are other more important things to consider suchs using good tools Power hacksaw blades have been carefully designed in order cut the toughest materials. And as you would expect from any quality security knife, are made to last and save time an money in the long run. Save time and work with the right tools as well Here, which allows you going back to your next project seamlessly!

Power hacksaw blades helps in making straight and right cuts. This is helpful to make sure that everything goes well in projects. These blades are designed to cut accurately. Each cut that you make will be effortlessly clean, as the blades stay sharp and able to deliver a precision trim. These kinds of hacksaw blades have a good deal more flex to them - meaning they can make the cut virtually in any material, ensuring you are not using multiple bits and tools for different kinds jobs. It is quite beneficial in terms of time-saving and cost reduction.

The power hacksaw blades require strength and long life; some of these are stronger or more durable than others so they are made up from a variety of types. The italicized type represents only heat-treated power hacksaw blades. After heat treatment they undergo a special procedure that makes them much tougher and harder to wear than regular blades. If you make a lot of cuts with your blades on projects, wonderful because this means the heat-treated steel can keep its edge sharp for quite some time.

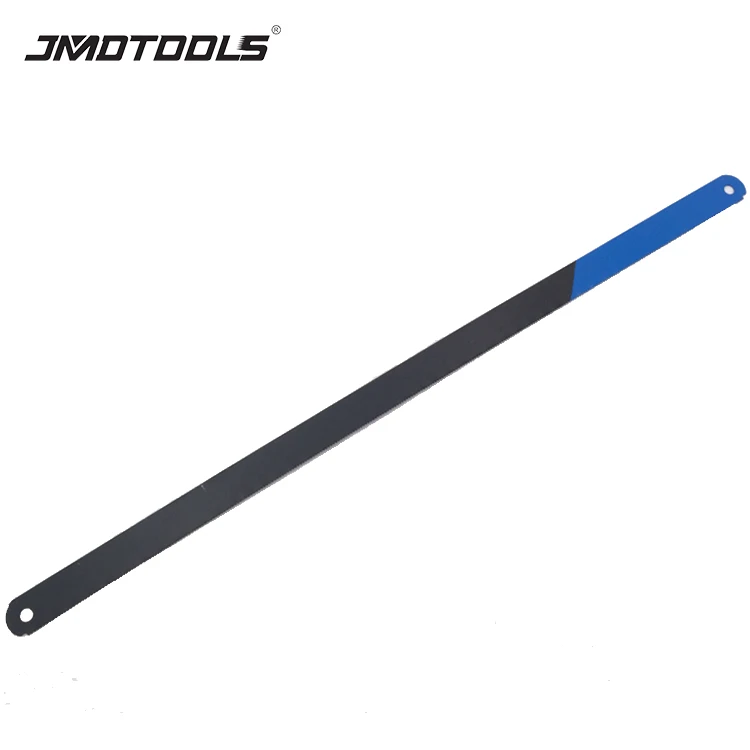

Image Credit: www. thatcables. Selecting the right power hacksaw blade for your application is important because a proper blade will optimize sawability, so you can either get material inside interrupted design cut sides or achieve straighter and more accurate sections. This is just in case you need to decide what type of cutting on which material at your anticipated thickness. It includes many types of hacksaw blades used for different materials and cuts. For example, if you have thicker metal that is more difficult to cut through, you can select a blade with large teeth suitable for your project. However, small teeth on the blade will get you cleaner and accurate cuts when working with thin metal.

Our factory has gained invaluable understanding and expertise by working some of the most renowned brands customers in the industry for over 20 years. Our vast experience has enabled us to gain better understanding of our clients' specific requirements and requirements, which enables to provide customized solutions and services. Through a variety of successful partnerships, we've refined production methods, strengthened quality control processes have developed a profound understanding the market's dynamics. Our long-standing renown in industry is a reflection of our commitment to excellence as well as our capacity to consistently deliver superior products power hacksaw blades.

We are proud to have achieved ISO9001:2015 certification our quality control system, in addition to BSCI and BEPI certifications. These certifications speak of our commitment to maintaining the highest standards of quality ethics, ethical sourcing, as well as environmental responsibility. The ISO9001:2015 certification ensures our quality management system is robust and efficient, assuring consistent power hacksaw blades quality. The BSCI and BEPI certificates demonstrate our commitment to sustainability and social compliance practices, providing our customers with the confidence that our products are produced under ethical environmentally friendly conditions.

In our manufacturing process, we implemented exceptionally rigorous quality inspection system. Each stage of production is thoroughly monitored examined ensure that only items of the finest quality leave our manufacturing facility. Our quality control team has state-of-the-art test equipment, and strictly adheres the protocols conduct extensive product testing. This methodical approach allows us to discover and rectify any quality issues before the power hacksaw blades reach customers. By ensuring that we adhere to these strict quality standards, ensure the satisfaction of customers as well as build lasting relationships built trust and confidence.

We have a team of highly-trained technicians are determined to study cutting-edge technologies all year. This team is dedicated to innovative thinking and is always in the know about the latest market trends. They are able to create unique products that exceed and exceed the market's expectations. In keeping ahead the market, we can ensure power hacksaw blades line remains fresh, competitive, and relevant. We are able to offer unique solutions investing in R and D.