As is the case with any saw blade, such as a concrete sawzall blade based on sharp teeth. They have strong teeth that are capable of breaking through the concrete. Basically this is the same as saying that cutting into feels like a knife through butter there! The concrete sawzall blade is unchallengeable, no hardness and thickness shall come in its way.

If you are buying a concrete sawzall blade, you will want to ensure that it lasts for as long as possible. After all, who wants to be buying new blades every time he turns around. Which means you better pick a blade that can withstand the abuse! Concrete Blades CONCRETE IS A MATERIAL that is very tough on saw blades, so the temptation to use a concrete cutting blade in your reciprocating cutters may seem more than reasonable.

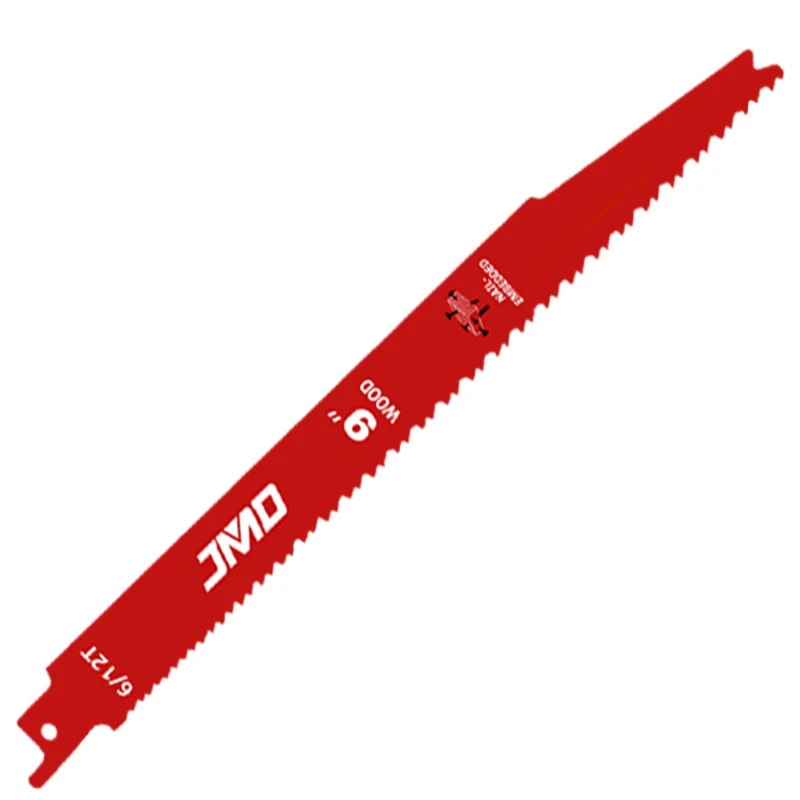

Sawzall blades last longer when they are more resistant to breaking. The best way of doing so is by using better materials! It has to be durable steel that will not break or get damaged and can do a lot of work. Moreover, a special rust protective coating for the blade is useful as well. This coating helps to ensure longevity through many jobs so you can save money over time.

This is due to the way how the blade has been shaped that it makes smooth cuts. The cuts should be sequenced evenly because the gapes in between will help avoid sticking dirt or debris and also it will lead to less shaking as you cut. Besides, the blade must be balanced level to let it run without a shake in operation. This balance balances and serves as a guide that you keep sharp during proper cuts.

Blade guards ensure that the blade does not come in to contact with your body by creating a shield over them. It should be Constructed out of High-Quality Durable Materials that are Hard for Your Dog to Chew through An anti-kickback feature ensures that the blade will not bounce back and potentially cause harm if it becomes wedged in concrete. These safety features are essential and will give you a good deal of confidence to even work with the sawzall blade without having to worry about hurting yourself.

Concrete cutting is not one size fits all. Wet and dry cutting jobs include in many job types. Which is why having a stable concrete sawzall blade that can manage both cutting variations with the same efficacy would be more of use in saving effort and time to carry it forward.

Wet cutting : It is the method of using water to cool the blade and reduce dust while you cut. This makes the work space neat and food cutting effortless. In dry cutting, no water is used at all. A top-rated sawzall blade should be able to handle both wet and dry cutting jobs with no problem. This variability allows you to save time and money on the different cutting tasks that require blades for a variety of needs.

Our factory boasts a highly competent technical team are researching cutting-edge technology throughout the year. This team committed to innovation and always keeping an eye on latest market trends. They are able to create new products that are innovative and meet or surpass expectations of the market. We make sure products remain competitive and up-to-date by staying up-to-date with latest trends. Continuous effort in R and D allows us to offer concrete sawzall blade solutions and stay on the forefront of our field.

With more than 20 years of experience working well-known brands and clients in business, our manufacturing facility accumulated invaluable expertise and insight. Our vast experience enabled us to understand the unique needs of our customers and expectations, which allows to provide customized solutions and services. Through number of successful partnerships we've refined production processes, improved concrete sawzall blade control processes, and developed a deep understanding of the market's changes. Our long-standing standing the field is a testament of commitment to excellence as well as our capacity consistently deliver superior products and services.

We are incredibly proud to have achieved ISO9001:2015 accreditation for quality assurance system as well as BSCI and BEPI. These certifications show our commitment to the very highest standards in quality ethics, ethical sourcing as well as environmental responsibility. The ISO9001:2015 certification guarantees that our quality systems are robust efficient, which in turn guarantees consistency in product quality. The BSCI certification and BEPI certificate prove our dedication to social compliance and sustainability business practices. Our customers can have confidence that the products they purchase were using ethical and concrete sawzall blade conditions.

When it comes our production process, we have implemented thorough quality inspection system. Each stage of production carefully monitored scrutinized to ensure that only products of finest quality leave our manufacturing facility. Our quality control staff is equipped latest testing equipment and follows strict protocols to conduct comprehensive product testing. This rigorous approach helps us discover rectify any concrete sawzall blade with quality before products arrive at our customers. Through the strictest quality standards, we guarantee satisfaction to our customers and establish long-lasting relationships based trust and confidence.